BUSINESS FIELD

사업분야

Powder Process

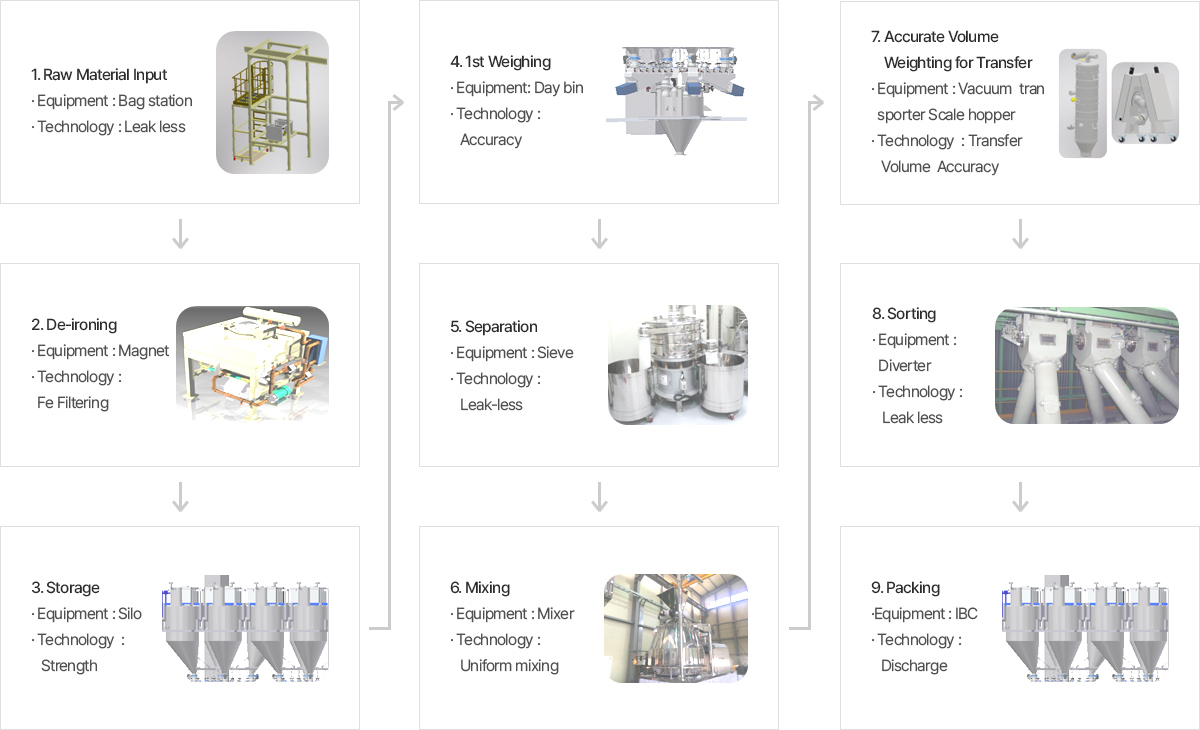

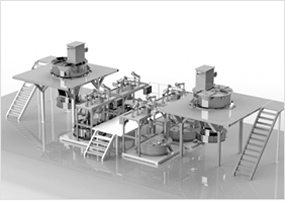

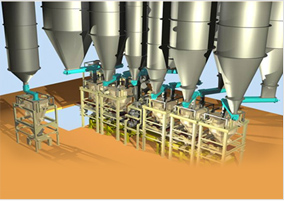

GlobalTech Co., Ltd. realized various types of powder systems for the last 30 years, and performed the E.P.C Process in the package order method from characteristic analysis/design on the raw materials to manufacture/installation/trial run and stabilization.We have the special know-how from the experience of handling not only raw materials for glass manufacture, but also special raw material particles from various fields such as secondary cell (cathode/anode materials)/semiconductors/chemical/pharmaceutical/ renewable energy, etc.

Especially, GlobalTech Co., Ltd. performs characteristic analysis for each raw material on the powers with special properties that are uncharacteristic and discontinuousin the powder research centerwhich is operated independently by the company, and applies optimum design condition based on the result data. Through continuous R&D on the characteristics of the powders that become the foundation of the industry, GlobalTech Co., Ltd. will provide optimized engineering service to enable the customers to have the best competitiveness.

-

Input/Transfer

-

· Input :

Bag discharge station, Dumping

-

· Transfer :

Air pneumatic blowing, Screw feeder, Vibrating feeder, Air slider, Vacuum transfer system, Bucket elevator

-

-

Crushing/Separation

-

· Crushing :

Jaw crusher, Tooth crusher, Hammer crusher, Ribbon crusher, ACM, Cone crusher, Roll crusher

-

· Separation :

Magnetic Separator, Metal detector

-

-

Storage/Weighing

-

· Storage :

Steel silo, Concrete silo, Hopper, Bin

-

· Weighing :

Floor scale, Suspended scale, Loss in weighing system, Gain in weighing system, Multi scale

-

-

Mixing

Paddle mixer, Pan mixer, Non-gravity Mixer, Ribbon blender, Paddle blender, and Shovel mixer

-

Packing

Auto packer, Paper bag, Vinyl bag, Ton bag, Pallet dispenser, Auto wrapping

-

Weighing

-

· Hard :

Cabling, Connection

-

· Soft :

DCS, PLC, HMI, MMI, MES Programming

-

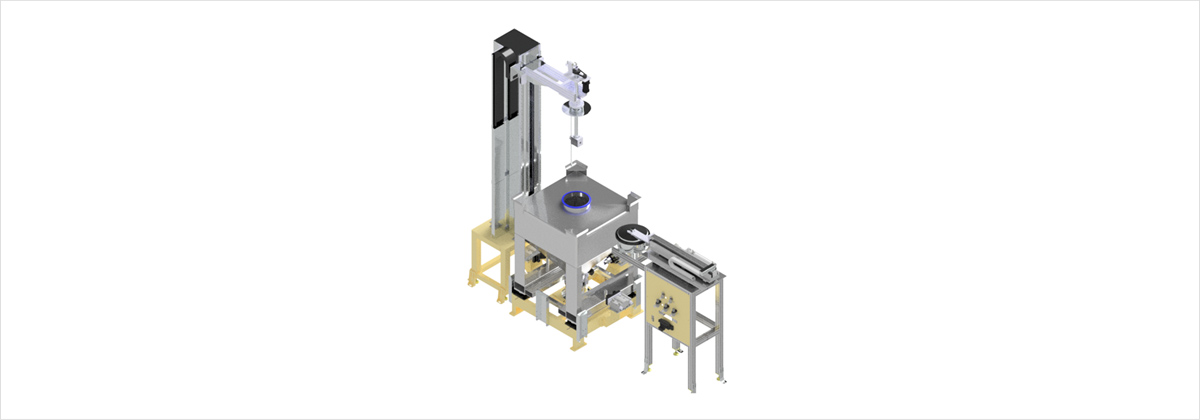

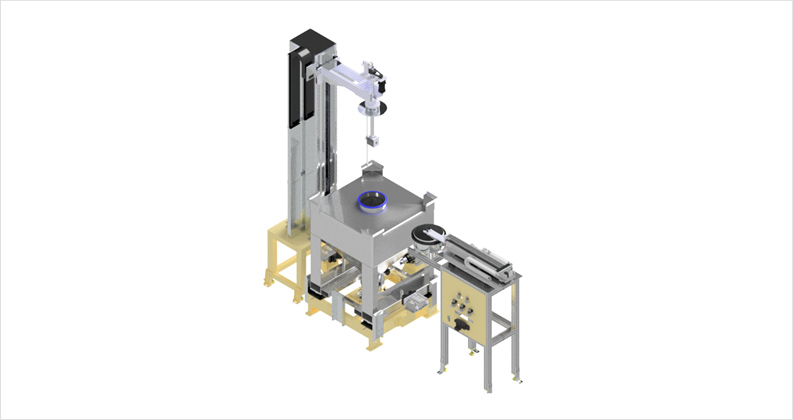

As the equipment for transferring the powder to the preferred location by applying VTS(Vacuum Transfer System), there is no leakage during operation, and the noise level is low to enable a comfortable operating environment. The quantity of the vacuum pump is determined according to the transfer distance and characteristics for each raw material, and Single or Dual Type is generally used.

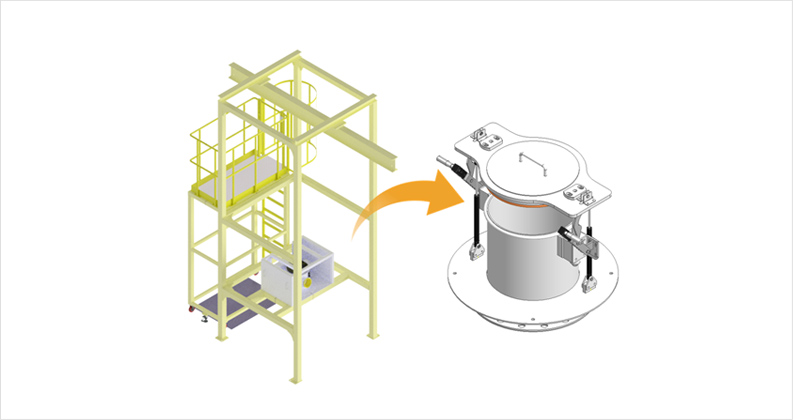

The IBC Cleaning system is applied with the automatic control system to enable accurate landing of the IBC by the fork-lift, and it is a dry-type Auto Cleaning System that is sprayed with high-pressure air without any blind spots while performing revolution and rotation in combination during the internal cleaning of the IBC. The dust generated during the spray is collected separately through the dust collector, and inflatable seal is applied for preventing the leakage to enable stable operation.

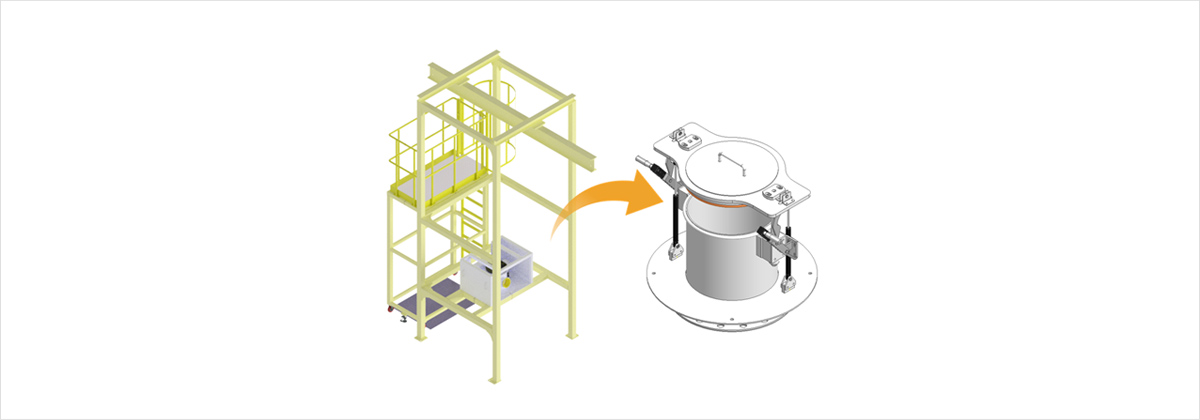

In the Big bag discharge station, the raw material in the Big bag is transferred by the hoist to arrive safely on the raw material input slot. The bag outlet vinyl is opened and inserted into the raw material input entrance, and as the raw material is discharged in the sealing state by the power cylinder, there is no external exposure to prevent any raw material scattering.

After applying basic data(Density, Shape, Size, Distribution, Angle of repose, Cohesion, etc.) andadditional factor(Cohesion, Heat transfer, Bonding, Wall friction, Electrostatics, Temperature, Fluid flow, etc.) according to the environment, it models the force and direction in consideration of the speed and location of tens of thousands of individual particles to realize the bulk-type transfer simulation. Through this,risk factors such as raw material discharge, particle size separation, agglomeration and stagnation section, etc. are identified in advance to enable optimum design.

- Notes!!

- DEM(Discreet Element Method) :As the analysis method on the raw material flow by the mechanical transport system, it is the simulation technique of enabling each raw material particle into bulk as a complex.

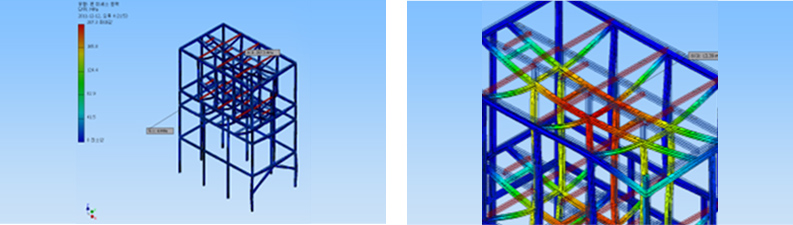

- · Structural design through CAE analysis (Stage 1)

- · Verification through structural diagnosis by an expert (engineer)(Stage 2)

- · Design after supplementation and re-verification (Stage 3)

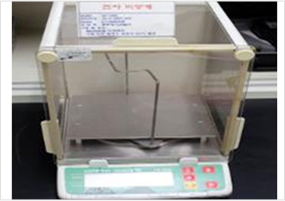

By using analysis equipment such as an auto power characteristic measuring instrument, etc., 12 items from sample analysis are collected into data to digitalize the flow-ability and flood-ability of the power through the correlation of each characteristic. The derived basic data is utilized as the basic data for realizing optimum equipment.

-

Moisture meter

-

Electronic gravimeter

-

Auto powder characteristic measuring instrument

-

Raw material characteristic measuring instrument

-

Silo Storage & Weighing System

-

Raw Material Transfer &Subdivision Weighing System

-

Silo Storage & Auto Weighing System

-

Ton-bag Feeding &Storage/Weighing System

-

IBC Discharge Station

-

IBC Discharge Station

-

Raw Material LIW Weighing System

| Kumho Petrochemical | CNT product blending facility installation work |

|---|---|

| Samsung SDI | Relocation of EMC S1 thermal raw material line to Gumi |

| Samsung SDI | Samsung SDI_Uiwang EMC high heat dissipation line moved to Gumi |

| Samsung SDI | Samsung SDI_EMC Expansion-Process Equipment Addition |

| Samsung SDI | Samsung SDI_EMC process S2 line Low Alpha dedicated |

| Samsung SDI | Relocation and expansion of Samsung SDI EMC process |

| Kumho Petrochemical | CNT powder transfer and packaging facility expansion |

-

- Person in Charge

- Hosung Um (Deputy General Manager)

- Kijung Kim(Team Leader)

-

-

- hs.um@gtkor.com

- kj.kim@gtkor.com