BUSINESS FIELD

사업분야

AGVㆍAutomation

What Is Automated Guided Vehicle?

An Automated Guided Vehicle (AGV) is both an unmanned transport vehicle and an unmanned logistics system that automatically transfers cargos from a designated place to another designated place without human intervention.

GlobalTech, a company specialized in manufacturing heavy-duty, high-precision, and special AGVs based on reliability and stability, is providing various and differentiated unmanned logistics solutions to the electronics, secondary battery, aviation, and steel industries.

-

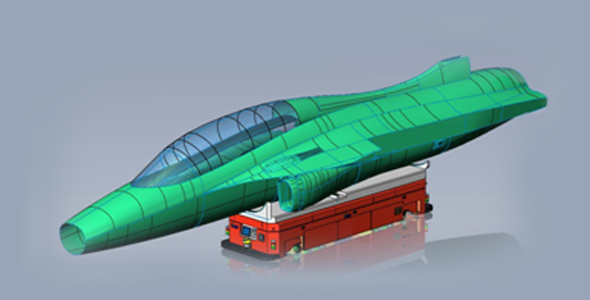

Heavy-duty AGV

Heavy-duty AGV capable of transferring up to 200 tons and special AGV capable of transferring large cargos

-

High-precision AGV

±5 mm stop accuracy and ±1 mm or less loading accuracy

-

AGV Type

Fork Type, Platform Type, Conveyor Type, Multi Type

-

Navigation

Laser, Natural(SLAM), Magnet(Bar, Spot, Tape), QR-code

-

Driving

Single, Quard, Differential, Multi

-

Battery

Lead-Acid, Ni-Cd, Ni-MH, Li-Polymer

-

Auto-warehousing

AGV-linked Automated Warehouse, ACS, WMS, and MES

- It is possible to minimize the frequent occurrence of errors and failures in advance by applying Kollmorgen's controller, which is proven to be the world's most stable and reliable control system.

- Joint technical support from GlobalTech and Kollmorgen headquarters makes it possible to mobilize rapid response to problems.

- The vehicle on-board diagnostic tool (TST: Truck Service Tool), a tool to check the status information on important AGV devices,makes it possible to easily read the AGV vehicle on-board status.

- We also offer an AGV operation diagnostic tool (VDT: Vehicle Diagnostic Tool), so all the histories that occur during automatic AGV operation are saved in real time (Black Box Data is created), making it easy to identify and reproduce the causes of the problems and minimizing maintenance time.

- Follow-up-management is organized to support customer requirements 24 hours a day, 365 days a year by securing systematic organization and personnel for prompt services.

- We support customers to efficiently operate AGV by running our own training program that provides the necessary knowhow for the use of various operating software and system maintenance tools (software) for AGV operation.

-

Gyeongnam Techno Park

(Mandrel Transfer, Magnetic Guide, 25Ton) -

Posco

(Coil Transfer, Laser Guide, 65Ton) -

Posco

(Coil Transfer, Laser Guide, 90Ton) -

Posco

Coil Transfer, Magnetic Guide, 65Ton)

-

Daewoong Pharm

(Pallet Transfer, Laser Guide, 1.5Ton) -

Hanwha Aerospace

(Telescopic Fork, Laser Guide, 1Ton) -

POSCO Chemical(Gwangyang)

(Pallet Transfer, Laser Guide, 1.5 Ton) -

For Samsung SDI Clean Room,

(Laser Guide, 1Ton)

POSCO Chemical(Sejong)

(Pallet Transfer, Laser Guide, 1Ton)

-

Iljin Bearing

(Outdoor Type Transfer, Laser Guide, 1.5 Ton)

| POSCO FutureM | Pohang cathode raw material transfer AGV |

|---|---|

| POSCO Chemical | Sejong anode material transfer AGV |

| POSCO Chemical | Gwangyang cathode material raw material transfer AGV |

| Samsung SDI | Gumi electronic material raw material transfer AGV |

| Samsung SDI | Ulsan secondary battery mixing process raw material transfer AGV |

| Samsung SDI | Cheonan secondary battery mixing process raw material transfer AGV |

| Samsung SDI | Tianjin secondary battery mixing process raw material transfer AGV |

| Samsung SDI | AGV for transporting secondary battery materials in Malaysia |

-

- Person in Charge

- Myungwha Hwang (Deputy General Manager)

- Chul Cho (General Manager)

-

-